في هذه المقالة سوف نناقش عملية تثبيت وتصحيح أخطائك في نظامين آلات صنع الثلج الأنبوبي بسعة 20 طنًا في إندونيسيا. تُستخدم آلات صنع الثلج الأنبوبي على نطاق واسع لأغراض التبريد والحفظ الصناعي، وهي ضرورية في قطاعات مختلفة، بما في ذلك تصنيع الأغذية والصناعات الكيميائية والبناء. يُعدّ التركيب والصيانة السليمان أمرًا بالغ الأهمية لضمان الأداء الأمثل وطول العمر الافتراضي للآلات.

آلة صنع الثلج الأنبوبي بسعة 20 طنًا قادرة على إنتاج ما يصل إلى 20 طنًا من الثلج يوميًا. تتميز هذه الآلات بكفاءتها وموثوقيتها وجودة الثلج الذي تنتجه، والذي يُستخدم غالبًا في التطبيقات التي تتطلب كميات كبيرة من الثلج، مثل حفظ الأسماك، وتجهيز اللحوم، وصناعات الأغذية والمشروبات واسعة النطاق.

تشمل المكونات الرئيسية لآلة صنع الثلج الأنبوبي المبخر، والمكثف، والضاغط، ونظام صنع الثلج. تعمل هذه الأجزاء بتناغم لإنتاج الثلج على شكل أسطوانات مجوفة (الثلج الأنبوبي)، وهو ما يُفضله الناس نظرًا لقدراته على التبريد السريع وسهولة نقله.

قبل البدء بتركيب آلة صنع الثلج الأنبوبي سعة 20 طنًا، من المهم التخطيط بعناية للتركيب. في هذا المشروع تحديدًا في إندونيسيا، أجرى فريقنا تقييمًا ميدانيًا لتحديد الموقع الأمثل للآلات. تشمل العوامل الرئيسية ما يلي:

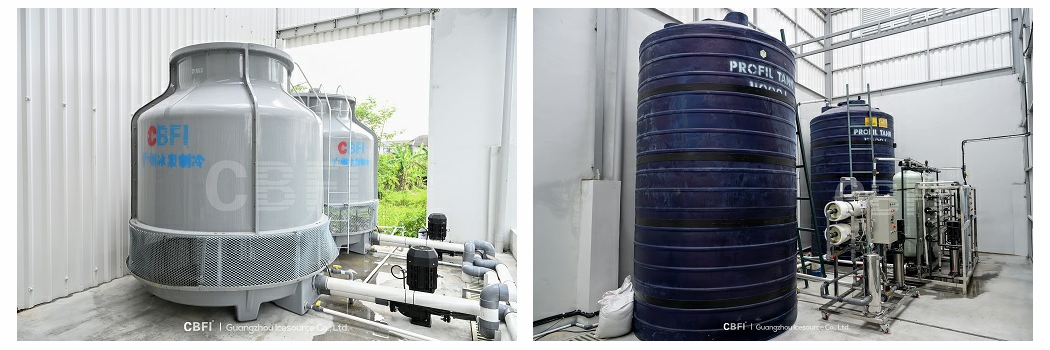

تتضمن عملية التثبيت عدة خطوات أساسية لضمان تشغيل الماكينة بسلاسة منذ البداية:

بعد اكتمال التثبيت، يحين وقت تصحيح الأخطاء واختبار النظام. تضمن هذه المرحلة أن يعمل الجهاز كما هو متوقع قبل تشغيله بالكامل.

تتضمن عملية تصحيح أخطاء آلة صنع الثلج الأنبوبي بسعة 20 طنًا ما يلي:

بعد تصحيح الأخطاء والاختبار، تُجرى أي تعديلات ضرورية لتحسين أداء الآلة. قد يشمل ذلك ضبط درجة حرارة الماء بدقة، أو ضبط دورة صنع الثلج، أو معايرة المستشعرات. الهدف هو ضمان كفاءة تشغيل آلة صنع الثلج الأنبوبي سعة 20 طنًا، وإنتاج ثلج عالي الجودة بأقل استهلاك للطاقة.

كانت عملية تركيب واختبار آلتي إنتاج الثلج الأنبوبي سعة 20 طنًا في إندونيسيا ناجحة، مما ضمن تشغيلهما بكامل طاقتهما. يُعدّ التركيب والاختبار السليمان أساسيين لضمان موثوقية وأداء طويلي الأمد. مع الإعداد الصحيح، ستوفر آلتا إنتاجًا ثابتًا وعالي الجودة من الثلج، مما يلبي الاحتياجات الصناعية لعميلنا.

إذا كنت تبحث عن آلة ثلج أنابيب موثوقة، فإن آلة الثلج الأنابيب بسعة 20 طنًا تُقدم حلاً مثاليًا لإنتاج الثلج بكميات كبيرة. التركيب والصيانة المناسبان ضروريان لزيادة عمر النظام وكفاءته.