معدات التجميد السريع الحلزونية من CBFI: سعة عالية وتطبيق واسع

مجمدات CBFI الحلزونية: نماذج حلزونية مفردة وحلزونية مزدوجة

مقدمة

تتميز معدات التجميد السريع الحلزونية من CBFI بتكنولوجيا التصنيع المتطورة والتشغيل الدقيق وأنظمة الأتمتة المتقدمة، مما يضمن الكفاءة العالية والأتمتة.

تصميمها العصري متعدد الطبقات يُعزز إنتاجيتها. يصل قطرها إلى 5.8 أمتار بارتفاع 40 طبقة، مما يوفر سعة تجميد تتراوح بين 300 و3000 كجم/ساعة، مما يجعلها من أكثر الحلول فعالية لتجميد الطعام بسرعة.

ينطبق على:

المأكولات البحرية، اللحوم، منتجات الأرز والدقيق، الفواكه والخضروات، مكونات الأطباق الساخنة، الأطعمة المقلية، المخبوزات، الوجبات الجاهزة، الآيس كريم، والمزيد.

الجزء الأول: الأنظمة الرئيسية لمعدات التجميد CBFI

نظام العزل ودرجات الحرارة المنخفضة

1. ألواح العزل عالية الكثافة

-

توفر ألواح العزل PIR المصنوعة من الفولاذ المقاوم للصدأ ذات الوجهين عزلًا حراريًا ممتازًا ومقاومة فائقة للحريق، وتتفوق على ألواح PU التقليدية.

-

شهادة FM، التي تضمن الاعتراف العالمي والامتثال لأعلى المعايير الدولية.

-

تم تجهيز الأبواب بعناصر تسخين لمنع تراكم الجليد وضمان التشغيل السلس.

2. تصميم منصة نظيفة

-

تتكون المنصة المعيارية من الفولاذ المقاوم للصدأ بالكامل، مع ألواح سفلية ملحومة بشكل مستمر ومقاومة للماء ولا تترسب.

-

يتميز بمنحدر كبير لضمان تصريف فعال وسهولة التنظيف والامتثال الكامل لمعايير نظافة الأغذية.

نظام الصرف الصحي والنقل

1. حزام شبكي ناقل

-

تم تصنيع الحزام الناقل من الفولاذ المقاوم للصدأ SUS304، ويستخدم سلك زنبركي حلزوني عالي القوة، مما يضمن المتانة وطول العمر.

-

يتم تشكيل أطراف القضبان باستخدام تقنية التردد العالي الآلية، مما يوفر تشغيلًا أكثر سلاسة ويطيل عمر النظام.

-

يوفر الهيكل المفتوح تهوية ممتازة وسهولة التنظيف، مع وجود حواجز على الحواف لمنع سقوط الطعام.

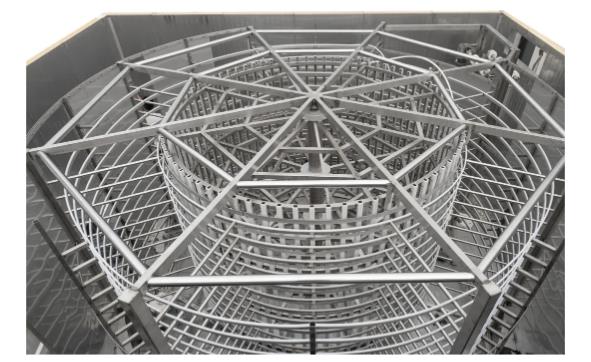

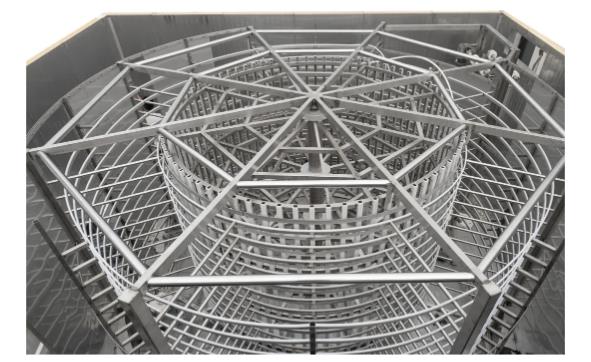

2. برج حلزوني

-

يضمن التصميم الذي يعتمد على الاحتكاك تشغيلًا سلسًا وهادئًا بدون أي إزاحة، مع كونه خفيف الوزن وسهل التركيب.

-

يتميز بمحور سفلي أرضي وجهاز حماية من التوتر متكامل لنقل سلس للحزام الشبكي.

3. جهاز الإرسال

-

تحكم متزامن متقدم ثلاثي الدفع مع محرك مسنن كبير وهيكل ملحوم بالكامل من الفولاذ المقاوم للصدأ 304، مناسب للأحمال الثقيلة والعمليات المستمرة.

-

مجهزة بنظام تحكم في السرعة بدون خطوات بتردد متغير، مما يسمح بإجراء تعديلات دقيقة على وقت التجميد استنادًا إلى نوع المنتج واحتياجات المعالجة.

-

يستخدم تكنولوجيا النقل المتزامن ذات التوتر الدقيق، مما يضبط شد الحزام تلقائيًا للحفاظ على الأداء الأمثل في ظل الظروف المختلفة.

4. جهاز الفحص الذاتي

-

يتضمن النظام آلية فحص ذاتي لمراقبة تشغيل حزام الشبكة. كما يتضمن إنذارات تلقائية للأعطال، وكشفًا عن مانع الانزلاق، ومراقبة فورية للأداء، مما يعزز السلامة والموثوقية.

نظام تبادل حراري فعال

1. المبخر

يتميز المبخر بتصميم محاكاة ديناميكي باستخدام أحدث برامج المبادل الحراري الاحترافية، مما يحسن كفاءة التبادل الحراري بشكل كبير.

-

الزعانف:

تعمل الزعانف المصنوعة من الألومنيوم عالية الحافة مع معالجة السطح المضلع على تعزيز قوة الزعانف ومنع الانهيار، مما يخلق تدفق هواء مضطرب لتبادل الحرارة بشكل أفضل.

-

أنبوب التمدد:

يضمن تمدد الماء عالي الضغط المتقدم تمددًا موحدًا للأنبوب، مما يحسن انتقال الحرارة بين الزعانف والأنابيب.

-

مساحة المبخر:

تعمل دائرة الملف المُحسّنة على زيادة مساحة سطح المبخر، مما يضمن أداء تبريد فعال يتجاوز خيارات السوق الأخرى.

-

الميزات الاختيارية:

متوفر مع خيارات إزالة الجليد بالماء، وإزالة الجليد بالفلور الساخن، وإزالة الجليد بالهواء (ADF) وفقًا لاحتياجات المستخدم.

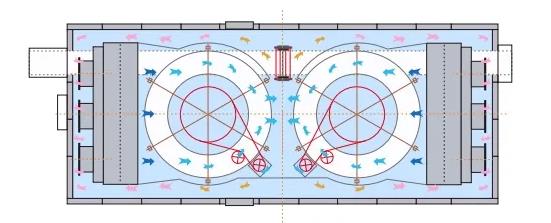

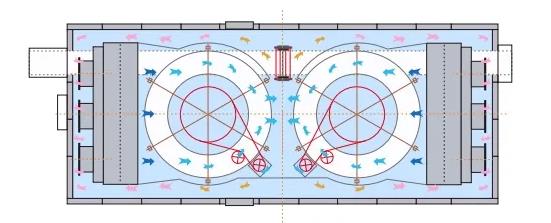

2. نظام مجاري الهواء

-

تم تصميم نظام مجرى الهواء لتوفير تدفق هواء مثالي، حيث يتميز بمراوح مقاومة لدرجات الحرارة المنخفضة للغاية وقنوات تدفق الهواء المصنوعة من مادة 304.

-

يضمن تدفق الهواء عالي السرعة ومنخفض الحرارة من المبخر اختراقًا وتجميدًا متساويًا للمنتج، مع الحفاظ على الملمس والجودة الفائقة.

-

تمنع تصميمات وأجهزة موازنة ضغط الهواء عند المدخل والمخرج فقدان الهواء البارد.

تكوينات إضافية موثوقة

-

يقدم نظام التحكم الذكي خيارات للتحكم من خلال PLC أو شاشة اللمس، قابلة للتخصيص وفقًا لاحتياجاتك المحددة.

-

يتم الحصول على جميع المكونات الكهربائية، بما في ذلك العاكسات وأجهزة الاستشعار، من العلامات التجارية الدولية والمحلية الموثوقة، مما يضمن الأداء الموثوق به.

-

يتوفر نظام التنظيف الذاتي CIP عند الطلب، حيث يقوم بتنظيف حزام الشبكة والإطار والألواح تلقائيًا لتسهيل الصيانة.

الجزء الثاني: أمثلة تطبيقية

تتضمن التطبيقات تجميد المأكولات البحرية، والأسماك الكاملة، ومكعبات السلمون المجمدة، والحبار، والروبيان، واللحوم، والدجاج الكامل، والدجاج المخبوز بالملح، وحلقات الدجاج المقلية، وشرائح لحم الخنزير المحشوة بالجبن، ومكونات الأرز والأطباق الساخنة، والزلابية، وكعك الأرز، وعيدان السلطعون، والنقانق، والمزيد.

لمزيد من أنواع التجميد السريع، يرجى الاتصال بنا لمزيد من التفاصيل.

الجزء 3: الاتصال بـ CBFI

في CBFI، قيمتنا الأساسية هي مساعدة عملائنا على النجاح وخلق قيمة طويلة الأمد. إذا كنت مهتمًا بمنتجاتنا، يُرجى إرسالها إلينا.

معلومات الاتصال والاسم والمتطلبات

عبر رسالة خاصة. سيتواصل معك مهندسونا بعرض سعر مخصص ومعلومات مفصلة عن المنتج.